PART

1: INSTALLATION

( 1 ) FRONT LCD COVER INSTALLATION

A.

PROPER TIGHTENING TENSION FOR THE FOUR SCREWS

ON THE LCD DISPLAY

MOUNTING AND CORRECT WIRE CONNECTION BETWEEN

THE PC BOARD AND

LCD. (INSTALL WITH THE RED MARK ON THE WIRE

TO CLOSE THE EDGE OF LCD.)

B.

CHECK SPEAKER WIRE IF IT HAS BROKEN OR UNCONNECTED.

C.

CHECK BATTERY WIRE IF IT HAS BROKEN OR UNCONNECTED

.

( 2 ) BACK COVER INSTALLATION

A.

CHECK THE METAL FRAME HAS PROPERLY MOUNTED

AND TIGHTENED TENSION.

B.

RECONNECTION AND REPLACEMENT OF ALL WIRES MUST AWARE AT ALL

TIME. (SHARP EDGE OF METAL FRAME MAY CUT

OFF WIRE.)

C.

CHECK IF THE SETTING KEYS ON THE TOP OF METAL FRAME HAS PROPER

SETTING ? FITTING AND CORRECT TIGHTENING

TENSION.

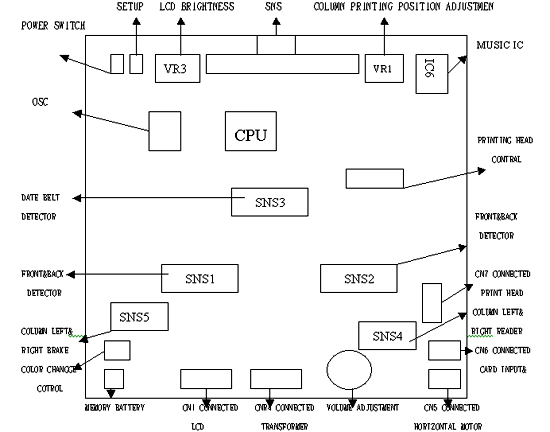

PART 2: PARTIAL ADJUSTMENTS ON THE PC BOARD

1.

LCD BRIGHTNESS ADJUSTMENT

A.

LCD BRIGHTNESS CAN BE ADJUSTED BY VR3 (TR-512

VR2) THAT IS ON THE LEFT SIDE OF PC BOARD.

2.

TIME CARD COLUMN UP?DOWN ADJUSTMENT

A.

VERTICAL PRINTING POSITION MIGHT BE ADJUSTED

BY VR1.

B. FAULTY SENSOR CAUSE NOT

PRINTING. ADJUST SNS5 SLIGHTLY UPON DOWN. TO CORRECT POSITION

(DO NOT ADJUST TOO HIGH OR TOO LOW OTHERWISE

EAT SN3)

3.

COLUMN RIGHT?LEFT ADJUSTMENT

A.

LEVEL PRINTING POSITION MIGHT BE ADJUSTED

BY SNS5 (MOVE THE SENSOR

UPWARD, THE PRINTING WILL SHIFT TO THE RIGHT;

MOVE THE SENSOR

DOWNWARD THE PRINTING WILL SHIFT TO THE

LEFT. FOR THE FINE ADJUSTMENT,

PLEASE USE THE FUNCTION TIME BUTTON #8;

TR-512 TIME BUTTON #7 IN WHICH

ALL SETS 48 FOR STANDARD.

4.

VOLUME ADJUSTMENT

A.

ADJUST VOLUMN BY TURNING, CLOCK WISE FOR LOUDNESS.

CHECK THE MUSIC ADJUSTMENT IF IT IS INCORRECT.

PART 3. PROPER PROCEDURES OF POWER

UP AFTER ASSEMBLY.

( 1 ) POWER ON

A.

PLUG THE UNIT INTO CORRECT POWER SOURCE AND TO POWER OR RESET. CLICK

THE

SWITCH ON DIFFERENT MODEL, MOVE THE ON/OFF SWITCH

TO THE LEFT TO TURN ON MACHINE.

TO RESET THE UNIT, SIDE THE ON/OFF TO THE RIGHT

AND WAIT FOR FEW SECONDS THEN SLIDE

THE POWER SWITCH TO THE LEFT (USE THE RESET BUTTON

ON THE BACK OF UNIT FOR TR-512)

(

2 ) ELIMINATION OF THE UNIT BREAK DOWN AND SHORT CIRCUIT TO THE

LOWEST POINT

A.

UNPLUG THE UNIT AND KEEP AWAY FROM THE POWER SOURCE WHEN DISASSEMBLE

THE UNIT.

B. TURN OFF THE MACHINE WHEN THE PRINTER HEAD KEEPS

RUNNING.

C. WHEN TAKING APART THE PC BOARD FROM THE METAL

PART DO NOT TOUCHING THE SOLDER POINT

ON THE BACK OF THE PC BOARD. THIS IS TO PREVENT

FROM THE MEMORY LOST OR SHORT CIRCUIT.

D. WHEN DISASSEMBLE PLEASE REMEMBER ALL THE CORRECT

CONNECTION. TO AVOID ELECTRICITY

SHORT CIRCUIT.

E. STABLE POWER ARE RECOMMENDED UNDER NORMAL USAGE

CONDITION.

( 3 ) BATTERY CHARGING

A.

THE BATTERY INDICATION WILL BE CONTINUALLY

FLESHING WITHIN ONE MINUTE WHEN POWER ON.

B. AFTER THREE MINUTE POWER

ON, THE BATTERY INDICATION WILL BE LIT OTHERWISE THE CHARGING

SYSTEM IS MALFUNCTION.

( 4 ) ELECTRICITY SHORTAGE AND RESTORING OF POWER

A.

WHEN THE ELETRICITY IS RESTORED, THE MACHINE WILL AUTOMATICALLY

RETUIRN TO NORMAL

CONDUCTION.

B. IF THE UNIT DOES NOT RETURN TO THE NORMAL CONDITION

OR DATA MISSING, PLEASE RESET

THE UNIT TO CHECK AGAIN. REFER TO PART3 (1) C

PART 4: SMPLE SERVICE MANUAL

(

1 ) NUMBER OR LETTER ARE INCOMPLETE DISPLAY ON LCD

A.

TO CHECK LCD IF IT IS DAMAGED OR CRACKED.

B. CHECK CONNECTORS OF LCD

IF THERE ARE NOT PROPERLY CONNECTED AT THE BOTH ENDS.

C. CHECK THE PC BOARD BATT1

WHICH CAUSED IC BREAK DOWN.

D. CHECK CPU CONNECTION TO

SEE IF THERE IS MOVEMENT.

(

2 ) TIME CARD CAN NOT BE INSERTED ATOMATICALLY

A.

CHECK THE DISTANCE BETWEEN PRINTER AND METAL

FRAME IF IT IS TOO CLOSE TO INSERT A

TIME CARD OR INTERRUPTED BY OTHER OBJECT.

B.

CHECK FOR THREE SETS OF SENSOR TO SEE IF THERE ARE MOVEMENT UNFREELY.

C.

TIME CARD INSERTING SPEED CAN BE ADJUSTED BY VR1 AS WELL AS LEVEL

PRINTING POSITION.

D.

CHECK THE HOLDERS BETWEEN SIDE OF THE METAL FRAME IF THERE ARE DAMAGED.

E.

CHECK PASSIVE ROLLER SET IF IT IS WEAR DOWN.

F.

TO CHECK INSERT CARD MOTOR IS WORKING.

G.

CHECK INSERT CARD GUIDE TO SEE IF THERE IS MOVEMENT UNFREELY.

(

2 ) THERE IS NO ACTIVITY FOR TR-SERIES WHEN ELECTRICITY SHORTAGE.

A.

CHECK BATTERY CHARGING SYSTEM IF ANY SHORT-CIRCUIT

HAPPENS.

B. CHECK BATTERY IF THERE

IS ANY SHORT CIRCUIT OR BROKEN WIRES.

(

3 ) DO NOT IDENTIFY THE RIGHT SIDE OF TIME CARD TO PRINT

A.

CHECK TWO SETS OF THE SENSOR SNS1?SNS2 UNDER

THE PRINTING HEAD SET HOLDER AND

TO SEE IF THE MOVEMENT IS UNFREELY.

B.

CHECK THE OPENING BELOW TIME CARD IF IT IS TOO SMALL GAP.

C.

CHECK THE PC BOARD TO SEE IF IT HAS HEAVILY SHOCK.

(

4 ) COLOR PRINTING ARE INCORRECT

A.

DUE TO INCORRECT PROGRAM SETUP.

B.

CHECK THE ELETROMAGNET UNIT ON THE LEFT SIDE OF METAL FRAME IF IT

WORKS UNFREELY.

C.

CHECK THE COLOR CHANGING STICK, THAT IS IN THE RBBON HOLDER, IF

IT WORKS UNFREELY.

D.

CHECK THE DISTANCE BETWEEN THE PRINT HEAD AND RIBBON GUIDE IF IT

IS TOO CLOSE TO

CAUSE THE RIBBON MOVING UNFREELY.

E.

CHECK A.B.S SPRING TO SEE IF IT IS INTERRUPTED OR ELASTICLLY.

(

5 ) LCD FAULT

A.

SLIDE POWER SWITCH COMPLETELY TO RESET THE UNIT AND CHECK AGAIN.

B.

CHECK THE CONNECTION OF WIRES FOR THE LCD IF IT IS NOT PROPERLY

CONNECTED.

C.

CHECK LCD CN1 LINE TO SEE IF IT IS INTERRUPTED

( 7 ) IMCOMPLETELY PRINTING

A.

CHECK THE SOFT PC BOARD OF PRINTER HEAD WHETHER THERE IS BROKEN

OR BAD CONNECTION.

B.

CHECK PRINTING HEAD NEEDLE TO SEE IF IT IS INTERRUPTED.

C.

CHECK PC BOARD IC3 IF THERE IS BAD CONNECTION OR BURN DOWN.

D.

CHECK THE COIL IF IT IS BALANK.

(

8 ) SETTING KEYS MALFUNCTION

A.

DISASSEMBLE THE PLASTIC SWITCH FROM PC BOARD AND RESTORE PLASTIC

SWITCH TO

MAKE SURE IT HAS PROPER FITTING ON THE PC.

B.

CHECK FOR ANY DUST OR SMALL METAL PART IN THE SETTING HOLDER.

(

9 ) POWER FAULT

A.

CHECK THE TRANSFORMER FUSE IF IT HAS DAMAGED.

B.

CHECK THE BATTERY IF IT HAS A SHORT CIRCUIT (TO TAKE OFF THE BATTERY

CONNECTION

WIRE FROM THE TRANSFORMER THEN POWER IN THE UNIT

AGAIN)

C.

CHECK THE TRANSFORMER IF IT IS MELT DOWN OR SHORT CIRCUIT.

D.

CHECK PC BOARD BATT1 TO SEE IF THERE IS ANY OXIDATION.

E.

CHECK POWER SOURCE AND EQIUPMENT.

(

10 ) SOUND DEFAULT

A.

CHECK THE SOUND SYMBOL “ “ ON LCD IF IT IS DISPLAY.

B.

CHECK THE PROGRAM IF THE SETTING IS INCORRECT.

C.

CHECK THE VOLUME ADJUSTMENT ON THE BACK OF THE UNIT IF IT IS PROPER

VOLUME.

D.

CHECK THE CONNECTOR AND WIRES OF SPEAKER.

E.

IT MIGHT BE CAUSED BY IC6.

F.

CHECK Q7 TO SEE IF IT IS BURNT DOWN.

(

11 ) INCORRECT COLUMN OF PRINTING

A.

USING AN INCORRECT TIME CARD TYPE (TOO THIN OR THICK ) AND USE VERTEX

STANDARD CARD

WOULD BE MOSTLY RECOMMEND.

B.

CHECK THE PROGRAM SETUP IF IT IS INCORRECT.

C.

CHECK TIME CARD WHETHER IT IS DAMAGED OR BEND, ESPECIALLY AT THE

BOTTON CORNER.

D.

CHECK THE DATE BELT WHETHER IT IS HINDERED OR DAMAGED.

E.

CHECK THE INSERT MOTOR OR VERTICAL MOTOR GEAR TO SEE IF IT IS INTERRUPTED.

(

12 ) RIBBON JUMPED

A.

CHECK IF THE PINS OF PRINTER HEAD INTERRUPTED RIBBON TAPE.

B. CHECK DISTANCE BETWEEN PRINTER HEAD AND RIBBON

GUIDE IF IT IS TOO CLOSE.

C. CHECK THE PRINTER HEAD HOLDER IF IT STOP ON

THE TRAN-AXLE.

D. CHECK THE TIGHTNESS OF RIBBON.

( 13 ) TIME CARD JUMPED IN CARD SLOT

A.

CHECK THE DATE BELT HAS COME LOOSE.

B. PULL THE DATE BELT IF THE MOVEMENT IS UNFREELY.

C. CHECK THE SNS3 IF IT IS ON PROPER POSITION.

D. CHECK THE CARD INSERTING MOTOR IF IT HAS BROKEN

WIRE.

( 14 ) THE PRINTER HEAD DOES NOT FUNCTION.

A.

CHECK THE PRINTER HEAD HOLDER AND SPINDLE FOR RIBBON HOLDER IF EITHER

OF THEM ARE

DAMAGED OR RUN OUT POSITION.

B. CHECK THE TRAN-AXLE GEAR AND RELATED GEARS ARE

ON RIGHT POSITION.

C. CHECK TIGHTNESS OF SCREWS UNDER THE SPINDLE

LOCK.

D. CHECK HORIZONTAL MOTOR TO SEE IF IT HAS BROKEN

WIRES.

( 15 ) TIME CARD GOES IN CARD SLOT BUT HAS NO PRINT

A.

CHECK THE DATE BELT IF IT IS ON RIGHT POSITION.

B. CHECK THE SOFT PC BOARD OF PRINTER HEAD IF IT

IS DAMAGED OR BAD CONNECTION

(CONNECT TO A WRONG SIDE OF CONNECTOR).

C. CHECK SNS3 IF THERE IS ANY BLOCKAGE OR NOT ON

RIGHT POSITION.

( 16 ) THE SITUATION NEED TO SEND

BACK TO OUR AGENT OR FACTORY FOR ANY NECESSARY

SERVICE IF THERE IS MALFUNCTION

AS BELLOW:

A.

CASE AND SPARE PARTS ARE BROKEN .

B. EITHER RUNNING TOO FAST OR TOO SLOW, NO ACTIVITY.

C. PC BOARD IS BURNT DOWN.

D. BOTH OF BATTERY AND TRANSFORMER BURNT DOWN OR

SHORT CIRCUIT.

E. WITHIN PART3 STILL COULD NOT FIND OUT THE PROBLEM.

(

17 ) LCD FAULT

A.

CHECK BATT1 IF THERE IS ANY OXIDATION.

B. CHECK R17, Q24 IF THEY ARE SHORT CIRCUIT.

( 18 ) PRINTING HEAD COULD NOT STOP

MOVING

A.

CHECK SNS5 AND SNS4 IF THEY ARE ON PROPER POSITION OR BALANK SOLIDB.

|